Product List

Mechanical Bar Screen also called as rainwater screen, is widely used to block and get rid of floating debris in rainwater pump station, wastewater pump station, water supply pump station and influent pump station of sewage treatment plant municipal wastewater treatment.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Rake Material: SS304,ABS or Customzied

Rake spacing: 20-100mm

Inclined angle: 75°

Motor brand: First-class motor, Nord or SEW is optional

-

Description

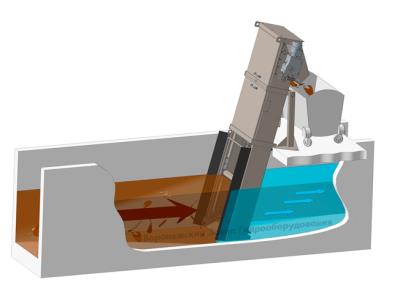

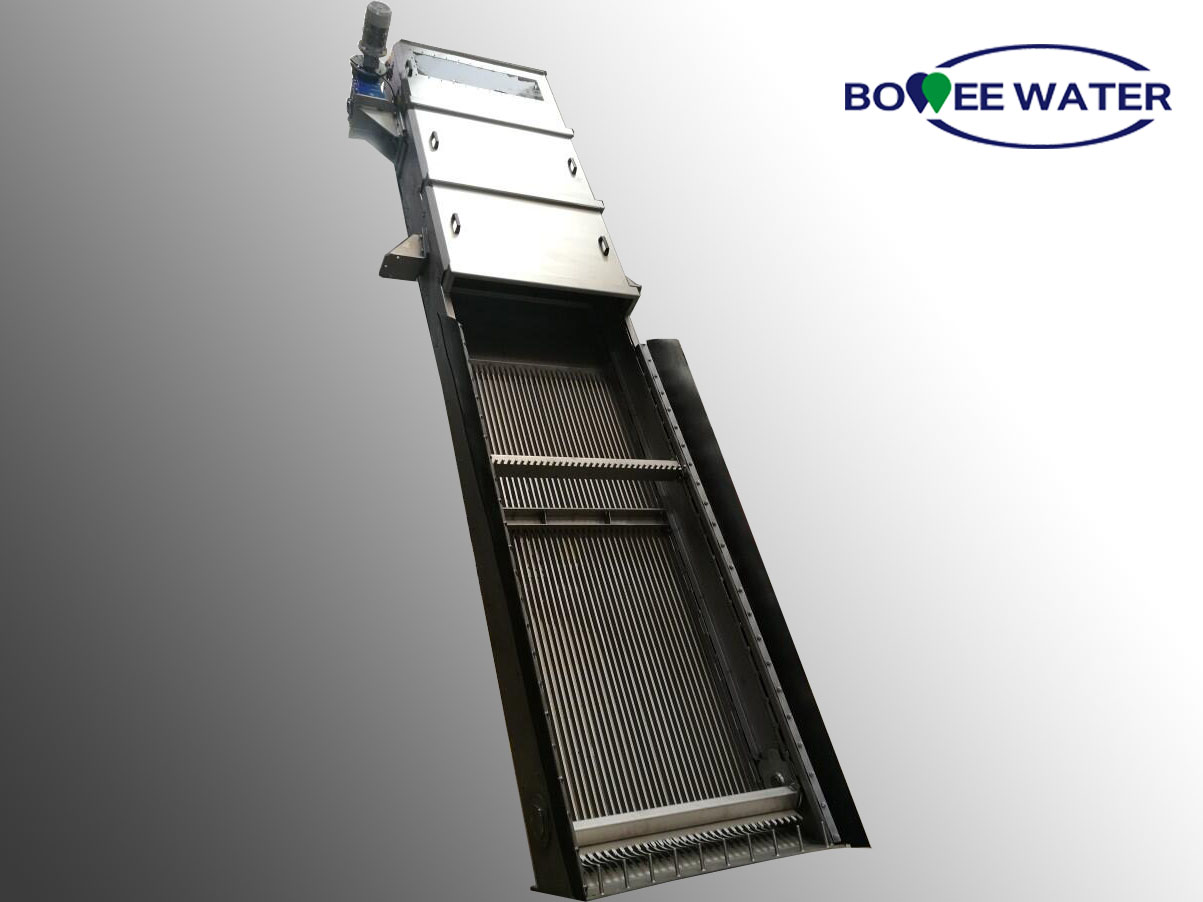

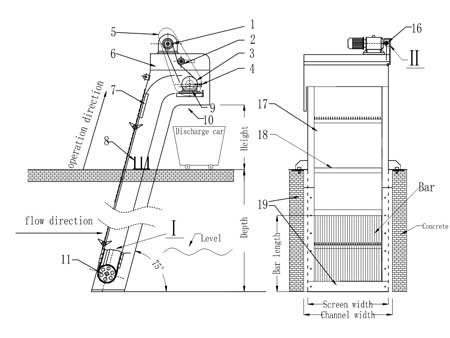

Mechanical Bar Screen also called as rainwater screen, is widely used to block and get rid of floating debris in rainwater pump station, wastewater pump station, water supply pump station and influent pump station of sewage treatment plant municipal wastewater treatment. Residue sizes larger than bar spacing get blocked by the screening surface while sewage flowing by, the tines of rake tooth plate go deep into the screen space. Residue blocking the screen surface will be raked up to the top by rake tines, under driven of driving chain and get discharged by gravity as they reach the top of the discharge outlet. Residues dropped from discharge outlet will fall into the conveyor or trash car for further processing.

-

Applications

· rainwater pump station

· wastewater pump station

· water supply pump station

· influent pump station of sewage treatment plant municipal wastewater treatment

-

Technical parameters

Model

Parameter

BWBS-800

BWBS-1000

BWBS-1200

BWBS-1400

BWBS-1600

BWBS-1800

BWBS-2000

BWBS-2200

BWBS-2400

BWBS-2600

BWBS-2800

Screen width(mm)

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

Channel width(mm)

900

1100

1300

1500

1700

1900

2100

2300

2500

2700

2900

Bar spacing(mm)

20-100

Installed angel

60-80°

Channel depth(mm)

2000-12000

Discharge height(mm)

600-1200

Rake moving rate

(m/min)

2

Material

SS304,SS316 or customized

-

Advantages

· Resistance to mechanical and hydraulic overloads due to high tensile design in comparison with other types of mechanized screens;

· High hydraulic efficiency achieved by using tear shaped bars that cause a pressure gradient to the mesh and across the bar spacing;

· Tear shaped profile as well protects the screen from waste jamming inside the filtering mesh. By using this design, such blockages can be removed by rakes allowing the screen operate freely;

· High reliability achieved by the absence of the rotating parts in the submersible part;

· Submersible parts like casing, bars, chains and rakes are made of stainless steel to improve corrosion resistance in aggressive environments of wastewater;

· Improved ergonomics: maintainability of the screen due to accessibility of the main units in operation and screen lifting without demounting.

-

Related Products